What is the best coolant for drilling an 8mm round hole?

Nov 24, 2025

Leave a message

When it comes to drilling an 8mm round hole, selecting the best coolant is crucial for achieving optimal results. As a reliable supplier of 8mm round holes, I've witnessed firsthand the impact that the right coolant can have on the drilling process. In this blog post, I'll share my insights on the various types of coolants available and help you determine which one is the best fit for your specific needs.

The Importance of Coolant in Drilling

Before delving into the different types of coolants, it's essential to understand why coolant is necessary in the first place. When drilling a hole, the drill bit generates a significant amount of heat due to friction between the bit and the material being drilled. This heat can cause several problems, including:

- Bit Wear: Excessive heat can cause the drill bit to wear out quickly, reducing its lifespan and increasing the frequency of bit changes.

- Material Damage: High temperatures can also damage the material being drilled, causing it to warp, crack, or become discolored.

- Poor Hole Quality: Heat can lead to poor hole quality, including rough edges, burrs, and inaccurate hole diameters.

By using a coolant during the drilling process, you can effectively dissipate the heat generated by the drill bit, reducing wear and tear on the bit, protecting the material being drilled, and improving the overall quality of the hole.

Types of Coolants for Drilling

There are several types of coolants available for drilling, each with its own unique properties and benefits. The most common types of coolants include:

- Water-Based Coolants: Water-based coolants are the most widely used type of coolant for drilling. They are typically a mixture of water and additives, such as rust inhibitors, lubricants, and anti-microbial agents. Water-based coolants are cost-effective, environmentally friendly, and provide excellent cooling and lubrication properties.

- Oil-Based Coolants: Oil-based coolants are another popular option for drilling. They are typically made from mineral oils or synthetic oils and provide excellent lubrication and cooling properties. Oil-based coolants are particularly effective for drilling hard materials, such as metals and alloys.

- Synthetic Coolants: Synthetic coolants are a relatively new type of coolant that is becoming increasingly popular in the drilling industry. They are typically made from synthetic polymers and provide excellent cooling and lubrication properties. Synthetic coolants are also environmentally friendly and have a longer lifespan than water-based and oil-based coolants.

- Dry Drilling: In some cases, dry drilling may be a viable option. Dry drilling involves drilling without the use of any coolant. This method is typically used for drilling soft materials, such as wood and plastics, or for applications where coolant contamination is a concern.

Factors to Consider When Choosing a Coolant

When choosing a coolant for drilling an 8mm round hole, there are several factors to consider, including:

- Material Being Drilled: The type of material being drilled is one of the most important factors to consider when choosing a coolant. Different materials require different types of coolants to achieve optimal results. For example, water-based coolants are typically recommended for drilling soft materials, such as wood and plastics, while oil-based coolants are better suited for drilling hard materials, such as metals and alloys.

- Drilling Speed and Feed Rate: The drilling speed and feed rate also play a significant role in determining the best coolant for your application. Higher drilling speeds and feed rates generate more heat, which requires a coolant with better cooling properties. Conversely, lower drilling speeds and feed rates generate less heat, which may allow for the use of a less aggressive coolant.

- Hole Quality Requirements: The quality requirements of the hole being drilled are another important factor to consider when choosing a coolant. If you require a high-quality hole with smooth edges and accurate diameters, you may need to use a coolant with better lubrication properties.

- Environmental Considerations: Environmental considerations are also becoming increasingly important in the drilling industry. If you are concerned about the environmental impact of your drilling operations, you may want to consider using a water-based or synthetic coolant, which are typically more environmentally friendly than oil-based coolants.

The Best Coolant for Drilling an 8mm Round Hole

Based on my experience as a supplier of 8mm round holes, I recommend using a water-based coolant for most drilling applications. Water-based coolants are cost-effective, environmentally friendly, and provide excellent cooling and lubrication properties. They are also suitable for a wide range of materials, including metals, plastics, and wood.

However, if you are drilling a hard material, such as a metal or alloy, you may want to consider using an oil-based or synthetic coolant. These types of coolants provide better lubrication and cooling properties, which can help to reduce bit wear and improve hole quality.

Ultimately, the best coolant for drilling an 8mm round hole will depend on your specific application and requirements. It's important to consult with a coolant manufacturer or supplier to determine the best coolant for your needs.

Conclusion

Choosing the best coolant for drilling an 8mm round hole is an important decision that can have a significant impact on the quality and efficiency of your drilling operations. By considering the factors discussed in this blog post, you can make an informed decision and choose the coolant that is best suited for your specific needs.

As a supplier of 8mm round holes, I am committed to providing my customers with the highest quality products and services. If you have any questions or need further information about drilling an 8mm round hole or choosing the right coolant, please don't hesitate to contact me. I would be happy to help you find the solution that is right for you.

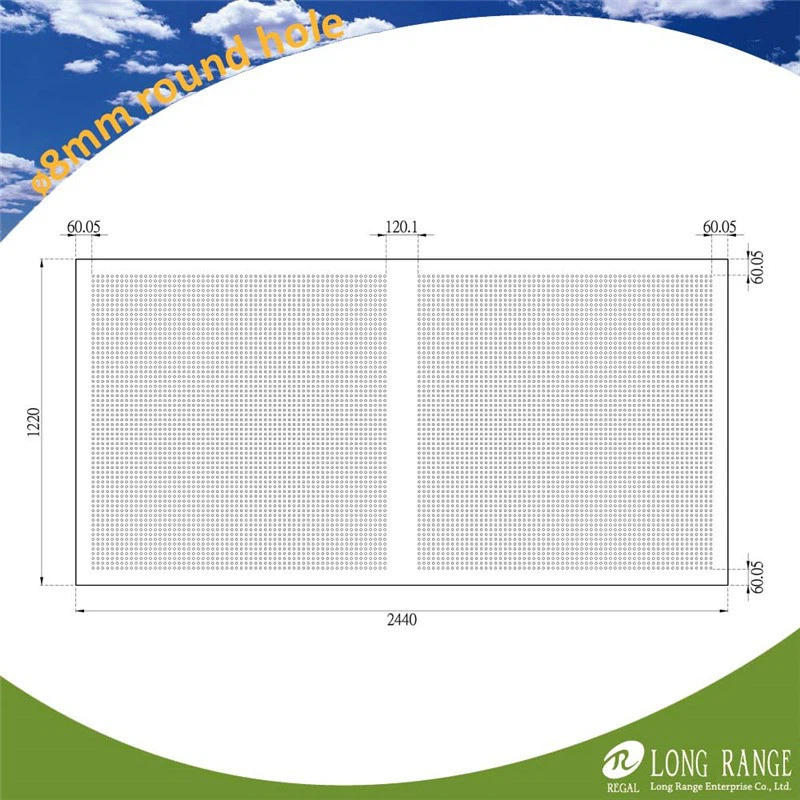

If you're interested in our Gypsum Board 8mm Round Hole, feel free to reach out to discuss potential procurement. We're here to assist you with your specific requirements and ensure a smooth purchasing process.

References

- "Coolants and Lubricants for Machining" by the Society of Manufacturing Engineers

- "Machining Fundamentals" by the American Machinist

- "Drilling Operations" by the International Association of Machinists and Aerospace Workers

Send Inquiry